TECHNOLOGIES

Max. part dimensions

CNC 3-axis milling

X 1300 / Y 670 / Z 625 mm / max. 500 kg

CNC 5-axis milling

X 650 / Y 765 / Z 520 mm / max. 500 kg

Milling

X 1800 / Y 600 / Z 500 mm / max. 500 kg

Jig boring

X 1000 / Y 1600 / Z 700 mm / max. 500 kg

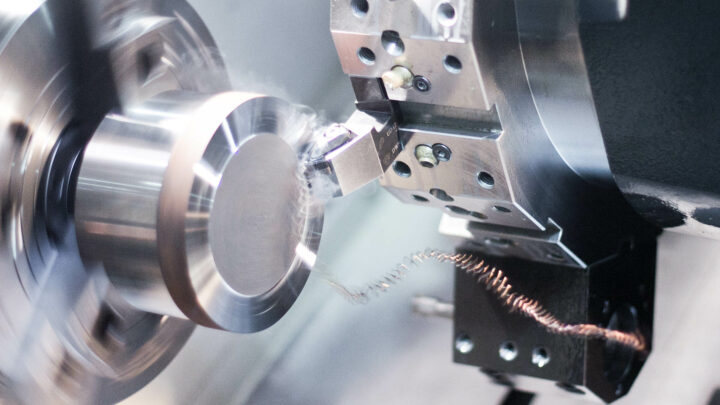

CNC turning

ø 700 / X 2000 mm / max. 500 kg

Turning

ø 900 / X 3000 mm / max. 500 kg

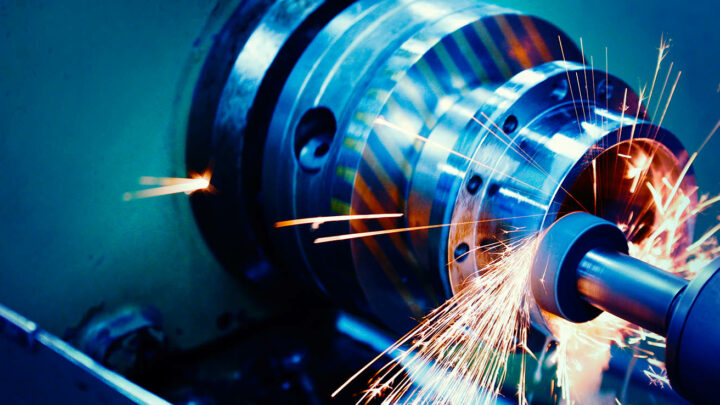

Hole grinding

otvor ø 360 / X 250 mm, dílec ø 400 / X 600 mm / max. 125 kg

Flat grinding longitudinal feed

X 1500 / Y 410 / Z 500 mm / max. 250 kg

Flat grinding circular feed

ø 670 / Z 300 mm / max. 125 kg

Outer round grinding

ø 500 / X 1500 mm / max. 250 kg

Inner, outer gearing

ø 1000 mm / modul 0.3 - 10 / sklon zubů ± 45° / max. 100 kg

Worms

ø 250 / X 1360 / stoupání 120 mm / max. 50 kg

Threads

ø 250 / X 1360 / stoupání 60 mm / modul 1 - 8 / max. 50 kg

Outer 6grooves

ø 150 / X 1360 mm / max. 100 kg

Inner grooves

otvor ø 40 - 310 / X 250 mm, dílec ø 400 / X 1800 mm / max. 100 kg

Balancing

ø 1200 / X 1800 mm / max. 400 kg

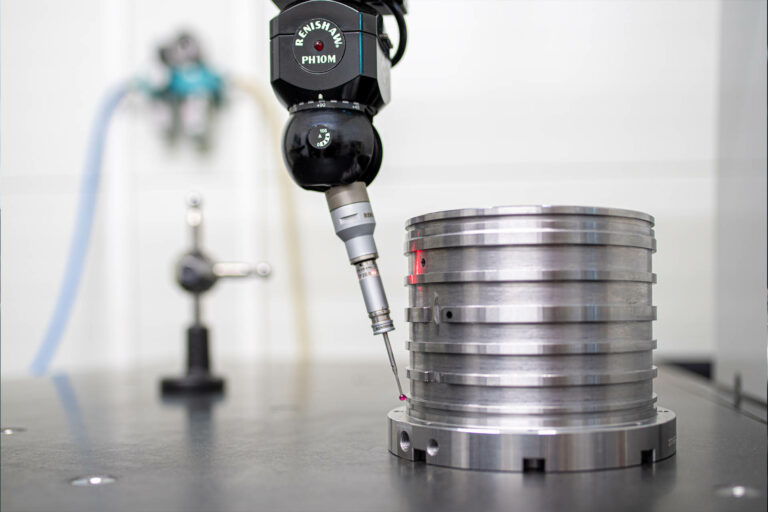

3D measurements

X 700 / Y 1000 / Z 500 mm / max. 250 kg

TECHNICAL INSPECTION – QUALITY

Technical inspection is carried out by 5 specialists. They are equipped with 3D measurements, digital height meters, length meters, microscope, roughness tester, hardness tester, gauges and manual measuring tools. We regularly pass customer and supervisory audits according to the ČSN EN ISO 9001:2016 standard at the certification body – TÜV SÜD Czech s.r.o.

Cooperation

Finishing and thermal treatment

In cooperation with other companies we provide all available methods of finishing and thermal treatment, e.g.: annealing, heat treatment, cementation, hardening, nitriding, phosphatizing, galvanizing, nickeling and painting. Smaller parts are annealed in our own furnace.

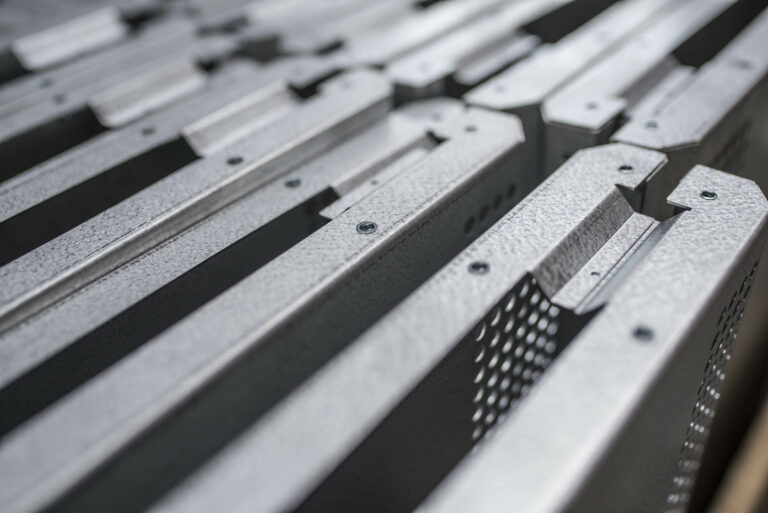

Comprehensive metal plate processing

Our affiliated company AM-Metal s.r.o., which shares the newly reconstructed production hall with us, provides comprehensive processing of metal plate products.

- Planar material cutting via laser

- Planar material cutting via punch punch preses/die-cutting

- Metal plate bending via folding brakes

- Fitting

- TIG, MIG welding

- Condenser welding

- Point welding

- Grinding

- Finishing through external cooperation

- Deburring, material cleaning and marking

- Metallurgical material slitting

Contact us

Address

PerFe CZ a.s.

Blanenská 171/57

Kuřim 664 34

(Areal TOS Kuřim-hall no.9)

IČ: 46346627

DIČ: CZ46346627

PerFe

Created ales@jedounek.eu